-40%

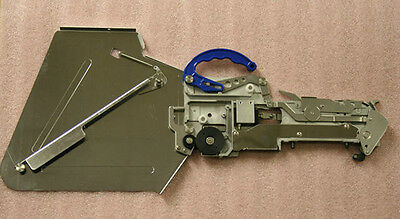

Semi Automatic PCB Foot Cutting Machine Lead Wire Cutting Machine 220V

$ 685.87

- Description

- Size Guide

Description

220V Semi automatic PCB foot cutting machineFlash point

1. Automatic lead wire cutting machine, can cut approximate 0.8-2.5mm height.

2. With thickness precision adjustment, suitable for different thickness of the PCB 0.8 - 2.5 mm.

3. Used for soldering pin after removal of the circuit board welding.

4. Multiple security measures such as three holes blade, super thick steel, synthetic glass.

5. Three holes blade make sure it is smooth and steady in high speed working.

The breadboard wipe cutting machine is mainly applied in cutting the unwanted pin after the welding of parts of apparatus and this machine is assembled by parts made with exquisite craftwork. The key parts are dealt with grinding , and the imported bearing assembled wipe cutting machine grinding consistency is excellent, the rotating speed of blade is fast and is very efficient and convenient to operate with little noise. The double lead rail is adjusted synchronously , the height of wipe cutting is adjustable and the outlook is attractive. “Continuous improvement, lasting and efficient, clients first” is our quality tenet, it is our honor to serve you.

Instruction of adjusting

1.Open the package and read the instruction carefully and check the accessories (refer to term 7 in the instruction)

2.Check the body of machine for any abnormal phenomena, if so , contact the local agent as soon as possible

3.After conforming the good connection of the case earth, plug in.

4.First adjust the double lead rail travel route biggest, unscrew the gland bush screw(gland bush screw is right-handed screw )with 8# inner hexagonal wrench counterclockwise,take out the blade gland bush and clean up both sides of tool apron, blade, gland bush with clean and soft cloth. Then place gently the blade on the base(surface up). Next ,place the blade gland bush on the blade, screw down the gland bush screw with 8# inner hexagonal wrench clockwise. When unloading the blade, use the enclosed dismantled stick to fix the tool apron.

5. Rotate the adjusting hand wheel, adjust the width between the lead rails, and place one wanted placode of wipe cutting machine on the entrance and exit port respectively. Rotate the hand wheel until the placode at both ports slide properly in the lead rail.

6.Four sets(three screws per set)assembling screws that are equipped on top of lead rail bland bush are used to adjust the thickness of placode. During the adjusting first unscrew three perch screws among them and put placode inside and then adjust two lower order screws besides until they fit and screw down the middle screw. Operation are the same for four sets and adjust placode to slide properly inside the lead rail

7.Adjusting of height of wipe cutting machine : screw down lead rail retaining screw and adjust the big screw cap until the distance between blade and lead rail meets the requirement then screw down lead rail retaining screw. When adjusting lower avoid any friction between lead rail and blade for fear of damage to blade.

8. The height of wipe cutting of wipe cutting machine was adjusted as 1.5mm when it leaves factory and the thickness of textile board was adjusted as 1.2mm. When adjusting is necessary please adjust according to method mentioned above.

Features

Blade jitter small

Pin cutting leveling

The 3 hole blade gland uses the triangle positioning principle, the blade is firmly fixed, not easy to loose, the high speed running condition, the blade does not slip, the operation is smooth, the cutting foot is accurate, the safety factor is high.

The whole machine is steady, low noise and low jitter.

The feeding guide rail of the fine steel is of high thickness, wear resistance, not easy to deform and prolong the service life of the machine.

Line type cutting.

Specifiction

Notice: We send a blade(0) as a gift.

Operations

1. Place the welded breadboard on the adjusted wipe cutting machine and insert the lead rail down the leading-in of lead rail.

2.Push dexter feed hand shank and push placode advance at constant speed

3.Repeat step 1,2 and finish cutting the welded placode.

Notice: When the placode moves avoid moving too fast, and moving too fast can directly shorten the use life of blade and even endanger safety.

Maintenance

Wipe cutting machine is the mechanic equipment of high accuracy and with high speed and the constant maintenance prolongs its use life

1.The rotating part needs constant lubrication.

2.Clean up the cut pin

3.If the transmitting triangle strap is damaged, it needs immediate replacement and the specification is (0-450)

4.The blade should not leave cutter head for too long, lubricate the cutter head when necessary if it leaves for several days.

Notice

1.When the machine is in operation avoid putting hands into the machine.

2. This machine must work in the state of good earth connection

3.Cut off the power when installing or dismantling blade or in case of emergency

4.Cut off the power in sace of a blackout.

5.This machine should not be used in humid, flammable, corrosive, dense bug dust-filled environment.

6. Non professional repairmen are not allowed to dismantle the cover to repair it personally .

7.Do not open the cover when the machine rotates.

8.Operate the machine according to instruction strictly; otherwise out factory takes no responsibility.

Item Include

(151005)

A set of 220V Semi automatic PCB foot cutting machine

A set of Blade

Shipping & Handling Details

Default Shipping Cost or Free Shipping Information:

▲

Default shipping cost or free shipping service is only for the customers from Canada or the lower 48 United States by Canada Post, USPS or the UPS Ground. Customers from other areas or needs other shipping ways, please contact us.

▲

Buyers from Guam, Puerto Rico, Virgin Islands, American Samoa, Alaska, Hawaii, PO Boxes, APO/FPO addresses or other countries/areas, there WILL be extra shipping costs, please contact us for more detailed information.

▲

Please make sure your address is valid for both UPS and USPS services. Any costs incurred because of incorrect or undeliverable address should be undertaken by buyer.

Handling Time:

Shipping is usually made in 1-3 business days after payments cleared. Orders are processed from Monday-Friday; Not on the weekends & public holidays.

Sales tax / Customs duties:

Any sales taxes or Customs duties are not included. If came out, they must be undertaken by the buyer.

Damage In Shipping:

Email or call us First! We will work with you to get the case resolved in the fastest method.

Return / Refund

If you are not 100% happy with your purchase, please contact Us. Please don't directly opened a request or case without informing us, or else, we will do some discounts on the warranty and other sales-services later on. Hope for your understanding.

Returns & Exchanges

▲

All returns must be made within 14 days of delivery date. Items must be in new, unused condition, with all original materials included with the shipment. A partial refund may be applied for opened or damaged items, depending on the condition.

▲

Items returned under the buyer’s remorse: The return shipping fee must be covered by the buyer; The original shipping cost will also be deducted from the refund. 15% restocking fee of the items purchase price will be charged.

▲

Returns that are the result of our seller's error: Buyer will receive a full refund of the item as well as shipping charges

▲

All returns require a RA (Return Authorization) number that will be given by our seller. Please contact with us at first for more details.

Defective & Damaged Products

▲

If product was received damaged or not as described, please send us some pictures or videos, so we could well understand your problem, then solve them for you ASAP. Besides, it's much helpful for us to claim with UPS, remind our related department to pay much more attention to packaging later on. Hope for your understanding.

▲

Replacement or refund of defective or damaged products can only be returned in exchange for the exact same product, or else, the purchase price will be refunded back to your original payment method.

▲

If an item is received damaged, customer service must be contacted within 7 days of receiving your item. All returns require a RA (Return Authorization) number as above.

Payment

eCheck Issues:

Payments via eCheck do not clear immediately. Usually you will wait 5-7 days after checkout for it to clear. Then we will arrange shipments for you.

Warranty & Feedback

▲

6 months' warranty for the machines, not for the consumables. We stand behind our products all the item, so even if your warranty period has expired, you can still seek for service or technical support from us with low cost.

▲

Any warranty shipping cost to us is responsible by buyer.

▲

Any shipping cost to buyer is responsible by the seller.

▲

We committee to the customer satisfaction and want to bring you the best purchase experience. If there is any problems, please contact us ASAP. If not, please leave us a positive feedback as it's very important for us. Thanks very much.