-40%

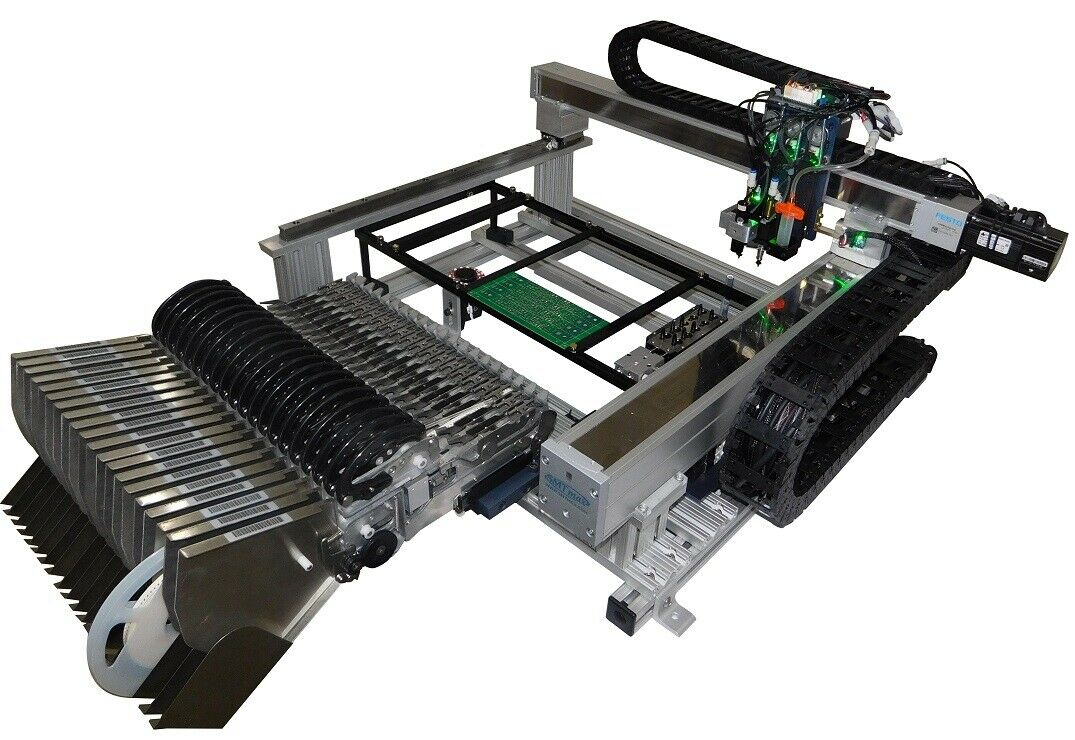

QM1100-B Dual Head Automatic Pick and Place Machine w/ Festo Ball screw

$ 5253.6

- Description

- Size Guide

Description

Description:The QM1100-B is our most popular desktop automatic pick and place machine with a full vision inspection system. This is our most economical and affordable pick and place machine made in the USA. The 40 feeder capacity and 12"(304mm) ×12"(304mm) working area is ideal for small to medium production batches. Equipped with dual placement heads, it offers a 3,000 PPH placement rate that is ideal for customers that are ready to start assembling in-house or for educational learning. The optional dispenser is another great feature for your prototyping requirements. Both hardware and software made by SMTmax at our Chino, California USA facility that allows for the potential of customization for other unique handling purposes. Contact us for more details or price quotes.

Specifications:

• 3,000 estimated P.P.H (parts per hour)

• 12"(304mm)×12"(304mm) working area (QM1100-B)

• Placement of 0402 standard (upgrade for smaller parts)

• Computer vision automatic centering system for IC's (SOP, QFP, BGA) and better placement of small parts

• Fully programmable digital Z-axis and Theta rotation angles

• X and Y axis 0.0005" resolution, 0.001" positioning, 0.045° rotational resolution

• 40 feeder capacity-standard for QM1100-B

• PCB board position correction with fiducial recognition

• Automatic post-place vision inspection

• CAD file convert function (in .CSV comma-delimited)

• Gerber file convert function (for paste dispensing option)

• 12 month full factory warranty - parts & labor

• Easy to use graphic software for quick programming. Programming can be done with down looking camera “teach mode” or

by importing Gerber file graphics or .CSV file.

• 110V AC 60Hz, or 220 V AC, 50Hz, 750 watts electrical (CE certified)

• 60-80 psi shop air required

• QM1100-B 400 lbs. net weight

• 40”x 40”x20” (not including feeders)

• Machine customization available (software and hardware)

• Made in USA by SMTmax.

Available options:

• Automatic nozzle changer

• Additional Pick up head

• Computer (with optimal requirements)

• Automatic dispensing head

• Five channels vibratory feeder

• Additional up looking cameras

• Five Channel 8mm strip feeder (for parts in cut tape strips)

• Five channel adjustable feeder (for parts in cut tape strips)

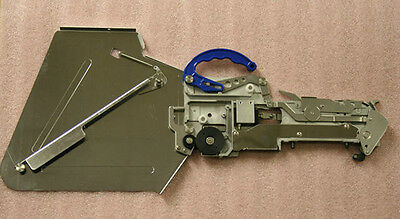

• Pneumatic feeders (8mm up to 44mm range)

• Additional (rear) set of 20 pneumatic feeder ports