-40%

Electrovert Econopak Plus Wave Solder System+Fire Ext.

$ 4749.35

- Description

- Size Guide

Description

-----------------------------------We have 1000's of Industrial/Laboratory equipment & parts items--See the categories on the left below

-----------------------------

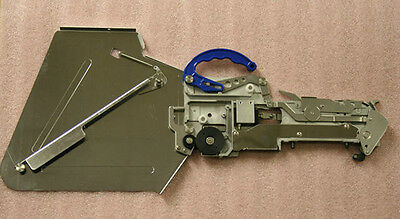

Electrovert Econopak Plus Wave Solder System Model # EPK PLUS/400F With Chemetronics Fire Suppression System Model # MICRO1-EV

FEATURES:

Model Number # EPK PLUS/400F

Manufactured By: Electrovert

See Table Below For Specifications

Estimated weight at

~5000

lbs, 189 by 69 by 84 inches raw

CONDITION:

Condition looks to be previously installed and complete to our knowledge.

CA# 2783

NOTES:

packing & shipping is very costly...

used & parts--

don't commit

if...

understand item condition...

ou can make an offer...

international is super costly & slow..

combined shipping...

anything electrical-more restrictions.

can't schedule shipping without...

delivery takes time...

query & purchase response time..

we make a mistake now & then...

TERMS & CONDITIONS:

buyer restrictions...

as-is-where-is...

no warranty...

buyer pays all P&S...

buyer takes all responsibility...

clear payment due in 7 days...

no returns without RMA #...

seller not liable for...

government restrictions...

insurance not included...

storage fees if items are left...

we reserve the right to...

SEARCH T&Cs

LINKS:

CAVLON ITEM CATEGORIES:

air compressors & parts

fans & blowers

bio energy fuel diesel components

bulk material handling

computer, network & telecom

construction equipment & tools

electric motors

electronic parts & assemblies

generators & backup power

hardware & fasteners

high voltage components

high pressure components

industrial automation components

industrial electrical components

lab& industrial ovens & furnaces

liquid pumps

machine tools

mechanical parts & assemblies

optical parts & assemblies

pneumatics

power supplies

rf radio frequency components

robotics

test and measurement equipment

ultrasonic equipment

vacuum pumps & components

valves and fittings

video components

wire, cable & shrink tubing

Electrovert is currently owned by

Speedline Technologies

.

This model is considered obsolete.

Below is the majority of the information available for the Electrovert Econopak Plus System we have been able to locate through the Internet.

We are not able to confirm the accuracy of this information as it is from a third party.

General Specs

Standard Power Sources:

220 VAC, 3 Phase, 60 Hz

440 VAC, 3 Phase, 60 Hz

380 VAC, 3 Phase, 50 Hz

Power Consumption:

Basic System:

EPK-I

1.5 kVa

EPK-Plus

2.0 kVa

Solder heaters:

8.4 kVa

Preheaters:

Vectaheat

10 kVa per heater

Radiant

7.5 kVa per heater

Preheat with exhaust

9.6 kVa per heater

Grounding Requirements:

The system must be provided with an electrical earth ground for the main power cabinet in accordance with local electrical regulations and standards. Ensure earths ground, or place a copper rod driven to earth on the supply side of any "earth trip" system. This procedure must comply with safety and fire regulations to shut down system if a shorting condition develops.

Compressed Air

Consumption:

Maximum of 0.35 L/s (0.75 cfm) with foam fluxer

Maximum of 2 L/s (4.0 cfm) with one Pyrometer

Maximum of 3.78L/s (8 cfm) With one air knife

Air Exhaust Requirements:

14.2 M

3

/min (500 cfm) at each of the two-152mm (6 in.) diameter vent ducts @ 0.5in. water gauge static pressure drop, located at the load unload ends of the system.

Cooling Fan Assembly:

4 fans @ 115 VAC

50 HZ:

2.6 M

3

/min (88 cfm)

60 Hz:

3.2 M

3

/min (105 cfm)

Conveyor Specs

Conveyor:

Speed:

0 - 4 mpm (0.5 - 12.5 ft/min)

Drive Motor:

1/4 hp at 90 VDC

(2.2 amps at 50 rpm)

Mechanical Clutch:

Disengages at 13.6 N-m (200in-lb)

Load Capacity:

18.1 kg (40 lb)

Standard Finger

Conveyor:

Finger Construction:

Flexible Titanium V-groove

Load Guide:

305 mm (12 in.)

Unload Extensions:

305 mm (12 an.)

Process Width:

50 - 400 mm (2 to 16 in.)

via handwheel mechanism

Adjustable

incline option:

4° - 7° (not compatible w/

150 - 200mm board clearance)

Entrance Height,

from bottom of unit:

827mm (32.5 in.)

Exit Height,

from bottom of unit:

1167 mm (46 in.)

Optional Pallet Conveyor:

Fixed Conveyor Angle:

6°

Process Width:

400 mm (16 in.)

[540 mm (21.25 in.) [in to pin]

Extended Throughput

Clearance option:

6 in. (150 mm) or 8 in.

(200 mm) above board

Entrance Height:

780 mm (30.7 in.)

Exit Height:

1185 mm (46.6 in.)

Optional Finger Cleaner:

Pump Motor:

1/40 hp @ 115 VAC

(1.25 amp @ 3000 rpm)

Pump Construction:

Polypropylene wet parts

with Teflon seals

Flow rate:

32.2L/min (8.5 gpm) maximum

Reservoir Capacity:

17 L (4.5 US gal)

Fluxer Specs

Standard Foam Fluxer:

Flux Capacity (25mm over aerator stones):

13 L (3.4 US gal)

Aerator Material

/Pore Size:

High-density Polyethylene

/ 10 -15µ

Compressed Air

Requirements:

345 kPa @ 0.45 M

3

/Min

(50 psi @ 15 cfm)

Adjustable Plates

(Aperture Adjustment):

13 - 64 mm (0.5 in. - 2.5 in.)

Flux and Thinner

Pump Flow Rats:

Adjustable from 94.5 to 944 ml/min

(0.025 gal/min to 0.25 gal/min)

Air Consumption:

Aerator:

0.06 M

3

/Min @ 35 kPa (2 cfm @ 5 psi)

Air Knife

(Foam Fluxers):

0.15 M

3

/Min @ 207 kPa

(5 cfm @ 30 psi)

Optional Flux

Density Controller:

Density Range:

PARR:

0.7 - 1.1

Float:

40 g weight:

0.75 - 1.0

50 g weight:

1.0 - 1.25

Temperature Accuracy:

± 2.5° C (± 4.5° F)

Temperature

Compensation Factor:

Programmable

Flux and

Thinner Pumps:

0.76 amps (115 VAC, 50/60 Hz max)

Flow Rate per Pump:

1.9 L/m (0.5 gpm)

Optional External

Fluxer Module:

Extended Conveyor

Rails:

432 mm (17 in.) (Lowers the

entrance height by 54 mm)

Exhaust Requirements:

500 cfm through 152 mm (6 in.) duct

Preheater Specs

IR Preheater:

Elements of the preheaters are wired in 3 sets. These seta are wired to switch on and off as a function of the preheat width zones parameter. Machines are wired such that zone 1 (standard IR platen only) must be on before the other zones can be used. This feature is standard on EPK-I units and optional on EPK-Plus units.

Heater Size:

400 mm (16 in.)

Total Power

Consumption:

7.5 kVa (220/380/440 V)

Temperature

Range:

ambient - 510° C (ambient - 950° F)

Max Temperature

Variation:

± 2.2° C (± 4° F) at idle conditions

Warm-up Time:

Approx 15 min. or less stabilize

Vectaheat Preheater:

This feature is standard on EPK-Plus units and optional on EPK-I units.

Heater Size:

400 mm (16 in.)

Power Consumption:

10 kVa

Blower Capacity:

160 cfm per blower

[two (2) blowers per preheater]

Lead Clearance:

13 mm (0.5) minimum

Maximum

Temperature Range:

ambient - 204° C (ambient - 400° F)

Warm-up Time:

Approximately 10 minutes to stabilize

Optional Pyrometer:

(Option for EPK-Plus Only)

This option is not compatible with 150 mm (6 in.) or 200 mm

(8 in.) bard clearance, adjustable incline, coN

2

tour

plus

, or Accuknife.

Location/Description:

Before Solder Bath / Read Only

Pyrometer Dot size:

10.2 mm (0.4 in.) at 152 mm

(6 in. ) from board

Range of Emissivity

via Manual Adjust:

0.5 to 1.0

Pyrometer Purge

Compressed Air:

Approx. 35 kPa (5 psi)

Pyrometer Cooling

(compressed Air):

Approx. 173 kPa (25 psi)

Air Consumption;

Pyrometer Purge:

0.015 M

3

/Min @ 35 kPa

(0.5 cfm @ 5 psi)

Air Consumption;

Pyrometer Cooling:

0.015 M

3

/Min @ 173 kPa

(3.5 cfm @ 25 psi)

Solder Pot Specs

Solder Heater Ratings:

Cast Iron Pot:

six-1.4 kW (at voltage

indicated on nameplates)

Solder Capacity:

With 63Sn 37Pb solder at operating level 12.5 mm (0.5 in.) below top edge of pot.

Cast iron Pot

with Lambda:

565 kg (1245 lbs)

Cast iron Pot with

Lambda and chip:

555 kg (1220 lbs)

Solder Operating

Temperatures:

ambient - 316° C (ambient - 600° F)

Solder Angles:

Standard:

6°

Optional:

4° - 7°

Maximum Temperature

Variation:

±1.7° C (± 3° F) at idle conditions

Warm-up Time:

3-4 hours for ambient - 260° C (ambient - 500° F)

(Times are voltage dependent)

Solder Level:

Standard:

Operator maintained, Manual

Optional:

Solder feed and level control mechanism for a constant level at approximately 13 mm (1/2 in.) below top lip of tank with pump stopped. Requires the Lambda wave and other functions to operate.

Solder Wire Feeder:

3 mm (1/8 in.) diameter wire recommended, up to 5 mm (3/16 in.) optional

Solder Nozzle Specs

Standard Lambda Nozzle:

Adjustable

Wave Height:

0 - 11 mm (0-7/16 in.)

Automatic Start/Stop

(EPK-Plus only):

Variable from 4.8-480 seconds

Optional Chip Nozzle:

MAx Wave Height:

0-9.52 mm (0-3/8 in.)

Optional Rotary

Wave Chip Nozzle:

Rotary Speed:

70 - 300 rpm

Nitrogen

Consumption:

100 cfh

Nitrogen Inlet Fitting:

0.5 in.

Wave Height:

3/8 in.

Motor Specifications:

1/17 hp @ 90 VDC, 0.62 amps

Optional Omega Nozzle:

Max Wave Height:

0 - 11 mm (0-7/16 in.)

Vibration Parameter:

0-100% of vibration of 50/60 Hz

Electrical System Specs (EPK-Plus Only)

Electrical Specifications:

Standard

Power Supplies:

220/440 VAC, 3ph, 60Hz

380/415 VAC, 3ph, 50Hz, earthed neutral

Grounding Requirements:

(earth or non-earthed)

Must be grounded in accordance with local electrical regulations and schematic requirements.

Radio Frequency

Interference:

Power supply and work area must be free of RFI noise

Microprocessor Specs:

80C286 Microprocessor:

Clock:

16 MHz

Supply Voltage:

Vcc min: 4.75 V

Vcc max: 5.25 V

Supply Current:

Icc Typ: 730 mA

Icc stby:

200 mA

Floppy Disk Drive:

one-3.5 in., 1.44 Mbyte

Hard Disk Drive:

one-210 Mbyte

Serial Interface Ports:

Ports A Electrosoft

Port B SIP

Notes

The RS-232C serial interface ports are located on the load end of the system cabinet.

Chemetron describes the Micro 1 as:

The Micro 1-EV Control Panel offers significant state-of-the-art advances in fire suppression system control. It is designed to deliver new peace of mind from the time of installation through operation, monitoring and maintenance. The Micro 1-EV is so simple and economical that it is practical for the most basic hazard; yet it includes a broad range of built-in features to handle the most complex hazards. Microprocessor based, the Micro 1-EV panel presents a wide range of options for automatic and manual operation, system status reporting and post operation feedback, plus advances in dependability. The Micro 1-EV Control Panel brings the latest state-of-the-art advances to automatic fire suppression systems. It is designed for FM-200, carbon dioxide, dry chemical, pre-action and deluge sprinkler systems. The Micro 1-EV is listed by Underwriters Laboratories, Inc. (UL) and Factory Mutual Research Corporation (FMRC). The Micro 1 -EV is designed to meet today’s pressing need for more sophisticated protection in the face of growing cost limitations. As a result, it makes the latest in fire suppression systems available, not only to better meet highly specialized needs, but also to provide protection for hazards where cost containment is a prime consideration.

For more information please visit the manufacturer. 1-EV

For a very detailed PDF document about specifications please visit:

Additional similar or related items may be available listed separately or on request.

This might be just what you need for your wave solder system application.

If you want what you see, make a bid or "Buy-It-Now" purchase now so you don't forget and miss it. (If an item is "Buy-It-Now"-only, you can make an offer for us to consider. If you really need what you see, do the "Buy-It-Now" before someone locks you out of it!